CUSTOMER PROBLEM

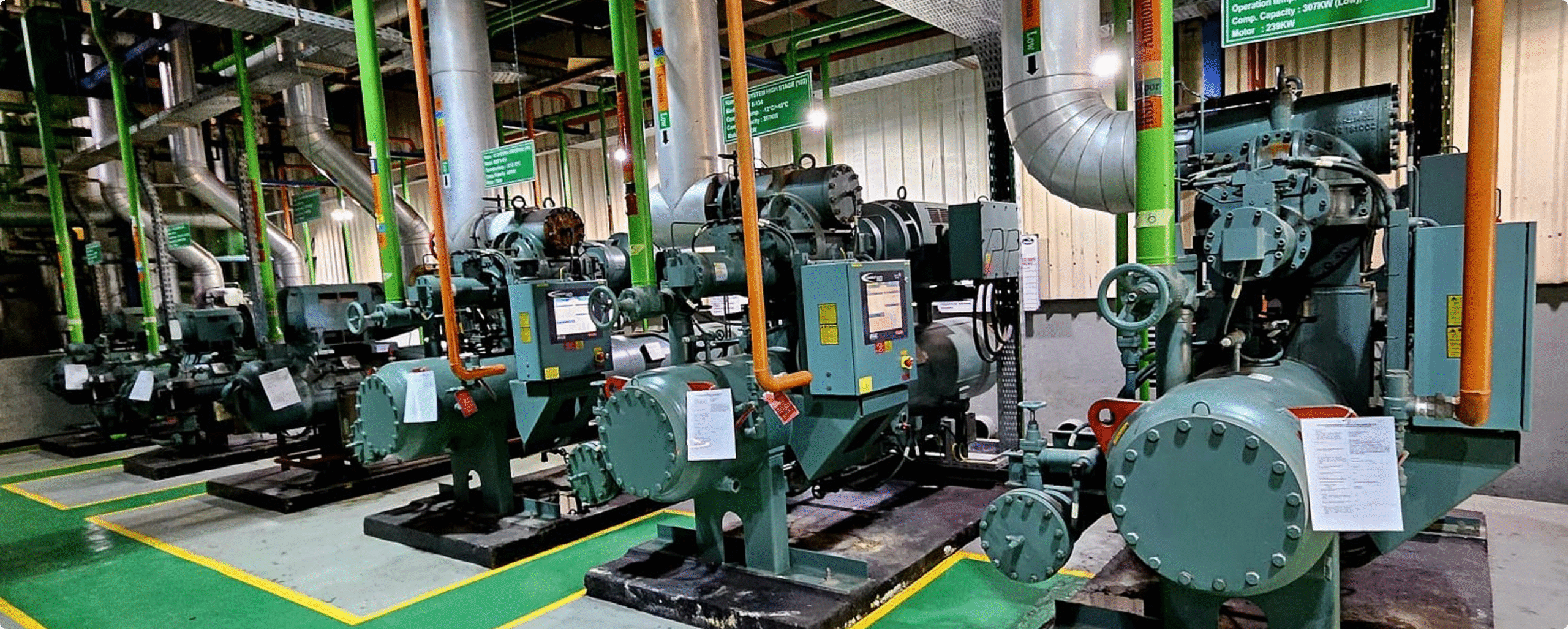

Cargills Ice Cream required comprehensive visibility over its critical cold chain

infrastructure and production line status. Manually monitoring numerous chillers

operating at different temperatures (-37°C, -47°C, chilled water) and key

production machines was inefficient. This lack of centralized, real-time data posed

a risk to product quality, energy efficiency, and timely response to equipment

faults.

UTECH’S SOLUTION

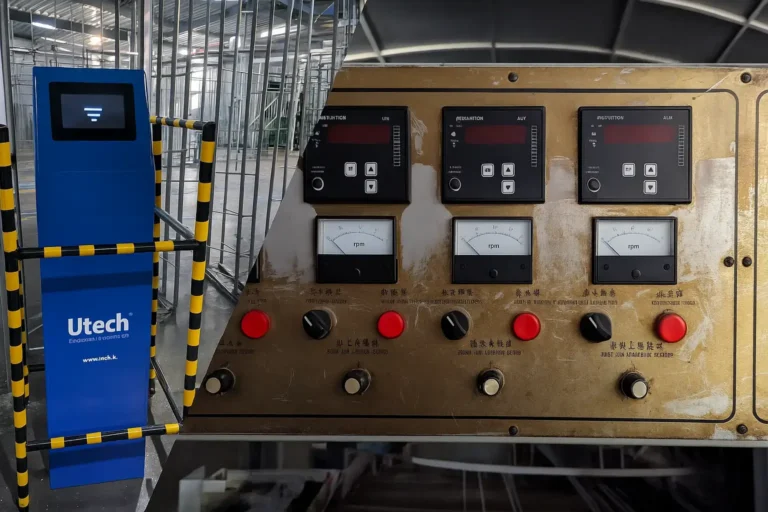

UTECH expanded Cargills’ existing monitoring system by integrating a wider

array of assets. We installed IoT gateways to connect nine new chillers and their

control panels via MODBUS, capturing critical performance parameters and alarm

states. Additionally, we digitized the on/off status of 15 key production assets,

including freezers and blasting tunnels, creating a unified view of the entire

operation on a single, secure web portal.

BENEFITS TO CUSTOMER

The solution provided Cargills with a holistic, real-time overview of their

production and cold chain. It enables proactive maintenance of chillers, preventing

spoilage and ensuring consistent product quality. By monitoring machine status,

they can optimize production flow and energy consumption. Immediate SMS/email

alerts for critical parameters minimize downtime and protect valuable inventory,

ensuring operational excellence.