CUSTOMER PROBLEM

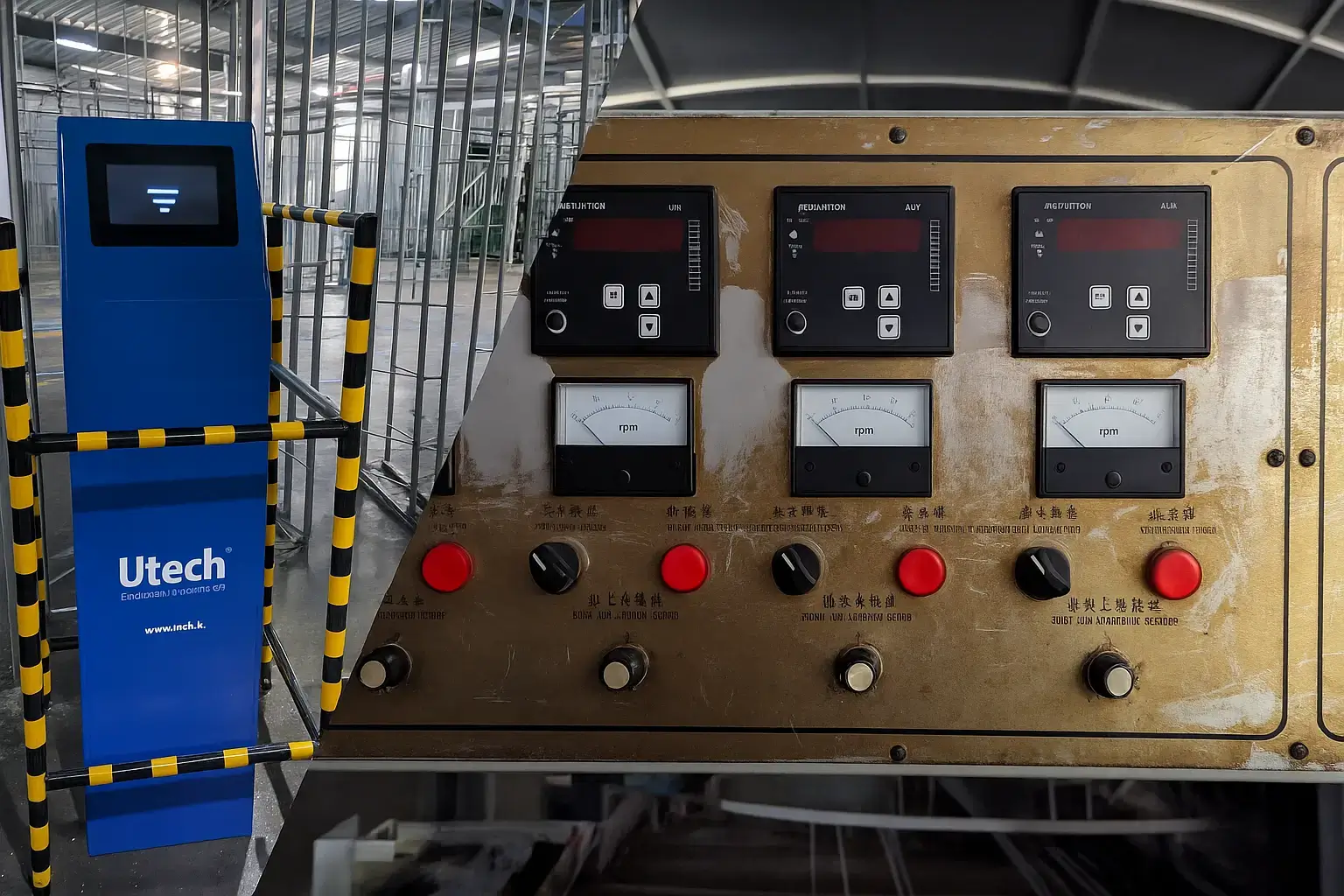

A textile manufacturing facility operated key production machinery, including rotary knitting and stenter machines, with limited visibility into their performance. Critical data on machine runtime, faults, production output, and process parameters like temperature and pressure were either manually tracked or not captured at all. This led to unplanned downtime, inefficient production planning, and an inability to pinpoint the root causes of quality and efficiency losses.

UTECH’S SOLUTION

UTECH implemented a comprehensive IIoT digitization strategy across both machine types. For the knitting machines, we connected to relay outputs to detect faults and installed RPM sensors. For the stenter machines, we integrated pressure sensors and a touchscreen HMI for manual batch data entry. Data from all assets is collected via UTECH 4G LTE gateways and visualized on a unified cloud platform with real-time dashboards and automated SMS alerts for faults.

BENEFITS TO CUSTOMER

The solution provided the textile facility with

unprecedented, data-driven control over their production floor. They achieved a

significant reduction in machine downtime through proactive fault alerts and

could accurately track production output and Overall Equipment Effectiveness

(OEE). This led to optimized maintenance schedules, improved production

planning, and enhanced operational efficiency across their knitting and

finishing departments.