CUSTOMER PROBLEM

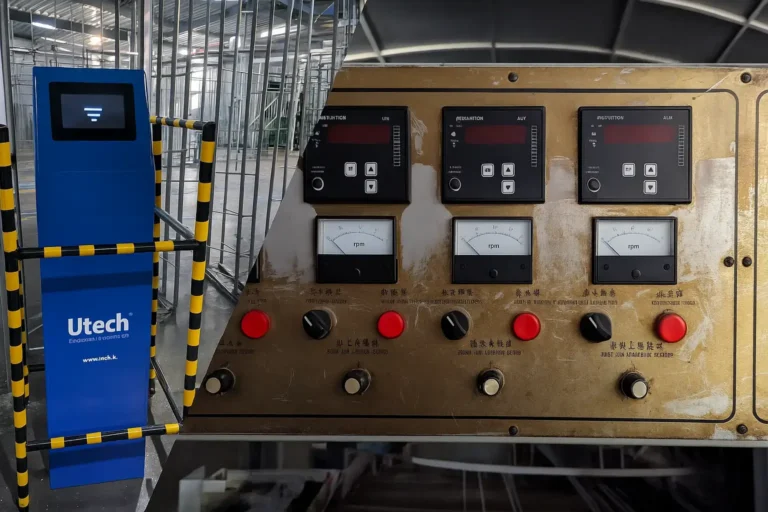

A glove manufacturing plant relied on manual tracking for knitting machine performance, making it difficult to monitor production output, downtime causes, yarn breakages, and overall machine efficiency.

UTECH’S SOLUTION

UTECH implemented a comprehensive machine monitoring system. We installed IoT gateways and sensors on the knitting machines to automatically capture critical data points, including power status, run/stop cycles, finished glove count via an IR sensor, and yarn breaks. This data is transmitted to a custom cloud platform, providing live dashboards and detailed analytical reports on performance versus targets.

BENEFITS TO CUSTOMER

The plant gained unprecedented insight into their production floor. The solution enables real-time tracking of output against hourly and daily targets, precise identification of downtime reasons, and data-driven error analysis. This leads to increased machine utilization, more accurate production planning, proactive maintenance, and a significant boost in overall operational efficiency and productivity.